The invention describes an innovative method for the separation and the purification of glycerol into fine and not fine chemicals. Glycerol and glycerol derivatives – considered by-products – are separated and purified through the use of the simulated moving bed (SMB) chromatography. The process designed by the inventors allows to reach high purity (99%), high productivity (the only manner to achieve an industrial scale production) and at a reduced cost.

Glycerol is considered a “waste” by-product. For instance, glycerol produced in biodiesel industry represents around 10% in weight of the total biodiesel produced. The price of refined glycerol has been decreasing significantly and now is painfully low. Therefore, development of sustainable processes for utilizing this organic raw material is imperative.

In parallel, value added compounds that might be produced from glycerol are produced in discontinuous (batch), complex and environmentally hazardous processes. Other compounds are commercialized at very high price, because there is not an industrial scale process to produce them.

The process works in a continuous mode, is scalable and includes a cyclic purification step which allows to reach high purity (99%) and high productivity as well as low energy consumption. The added value compounds produced are all purified and simultaneously in the same process.

Specifically, the process has a set of differentials:

- it does not use dangerous reagents or cause serious damage to the environment;

- it does not generate waste industrial products;

- operates at low temperatures and pressures;

- can reduce energy consumption by up to 50%;

- can reduce greenhouse gas (CO2) emissions by up to 70%;

- it is at least 80 times more productive than conventional processes.

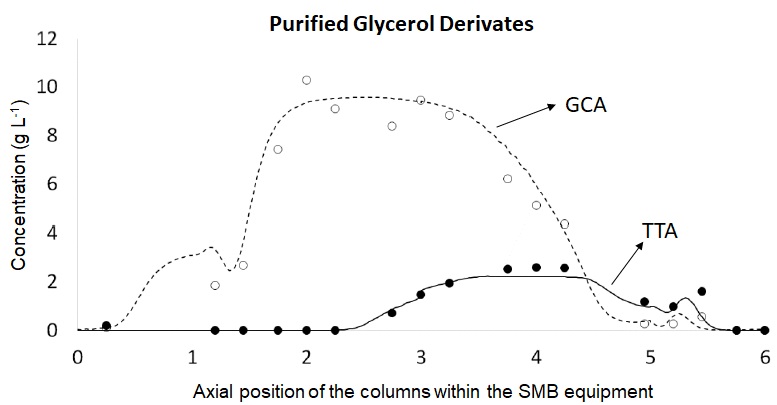

The application of simulated moving bed chromatography to separate and purify glycerol allows to obtain:

- Tartronic Acid (TTA) and Glyceric Acid (GCA). These compounds are sold at a premium price because their production processes do not have industrial scale.

- Dihydroxyacetone (DHA), Hydroxypyruvic Acid (HPA), Glycolic Acid (GCO), Oxalic Acid (OXA), Mesoxalic Acid (MEO), Glyceraldehyde (GLA) and Glyoxalic Acid (GOX). The price of DHA is at least 40 EUR / Kg. It has a high demand because it is the main component of self tanning products. Production processes have industrial scale but are ineffective, work in batch mode and are pollutant.

Generally speaking, these compounds are applied in the Chemical, Fine Chemical, Cosmestic and Pharmaceutical industries.

A proteção dos direitos de propriedade industrial é cofinanciada por: