The technology developed is based on the use of a new cellulose derivative (Long-chain Cellulose Ester - LCCE) as a totally eco-friendly non-fluorinated hydrophobic additive for dry-cleaning water repellency finishes in any type of textile composition: cotton, synthetic textiles and mixtures thereof. This new additive/formulation can be applied for repellent/water proofing finish on clothes by the simple and conventional dry-cleaning process. Additionally, there is no need to use of crosslinkers to anchor the additive to textiles, nor pre-treatments. Hydrophobic (repellent) textiles are thus obtained, with easy and self-cleaning properties, through a traditional dry-cleaning process totally fluorine free.

The demand for garments with easy-cleaning/self-cleaning properties has been increasing. These functionalities are directly related to the repellency (hydrophobicity) of the substrate. On textiles, the repellent finishes are achieved through compounds that, upon adsorption onto the fibres, reduce the associated surface Gibbs energy. These compounds are generally polysiloxanes, organosilanes, polytetrafluoroethylene, fluorinated polyacrylates, or fluorosilicones, with great prevalence for fluorinated compounds. However, fluorinated compounds have negative effects on the environment and also the modification of the surface by these processes implies a pre-treatment or the use of other additives such as crosslinkers. On the other hand, in synthetic fibers generally the anchoring of these finishes is very difficult to achieve, limiting these approaches to cotton fabrics.

- Water repellency finishes in any type of textile composition: this new additive/formulation can be applied in cotton substrates, synthetic textiles substrates and mixtures thereof.

- Application process: this new additive/formulation can be applied on textiles by the simple and conventional dry-cleaning process without requiring any pre-treatment.

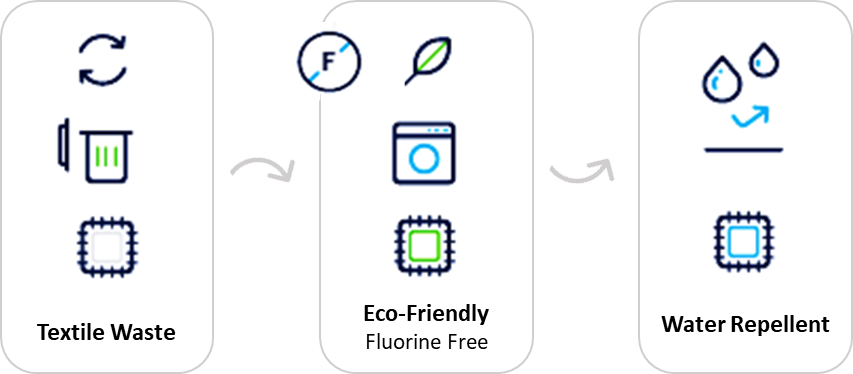

- Totally fluorine free and eco-friendly formulation: it contains a new additive obtained from cellulose and natural fatty acids.

- Sustainable formulation: the new additive can be synthesized by using textile wastes promoting sustainability and a circular economy.

Dry-cleaning processes.