Um sistema baseado em dados específicos de cada grávida, criado para prever e prevenir lesões maternas relacionadas com o parto apoiando a tomada de decisões médicas.

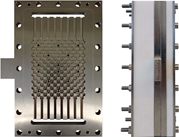

The current technology consists of an innovative electrochemical device featuring enhanced mass transfer, leading to higher efficiencies in generating reduced products at the cathode and/or oxidized products at the anode. This device employs stacked plates, including one plate serving as a fluid distributor composed of a particular fluid network capable of inducing convection and promoting a laminar chaotic flow regime.

It finds application in various electrochemical processes, including but not limited to water electrolysis to generate hydrogen, carbon oxides electroreduction to form fuels, nitrogen oxides electrooxidation to form fertilizers, organics electrooxidation to produce added-value chemicals, and inorganics electrooxidation or electroreduction to form oxidants.

The productivity of conventional electrochemical reactions is conditioned by the mass transfer rate of reactants and products to and from the electrodes. Therefore, there is a need to innovate and achieve new electrochemical devices that promote mass transfer. Typically, mass transfer is fully dependent on diffusion and convection in conventional cells. However, most conventional technologies introduce flow obstacles to enhance interfacial contact and fail at creating convection.

In the current invention, a fluid distributor plate with an innovative design promotes chaotic convection, leading to mass transfer enhancement at laminar flow regimes.

The technology entails an electrochemical device designed to significantly improve mass transfer, enabling volumetric mass transfer coefficients up to 200 times higher than those achieved by existing electrochemical devices. Ultimately, the new device is capable of improving the rate and selectivity of a multitude of electrochemical reactions.

Furthermore, the new device is modular and flexible, being easy to scale-up. Several devices can be placed in series (numbering-up) and the length of the network where the fluid flows can be expanded. It also has enhanced energy performance, promoting lower electrical energy consumptions compared to conventional devices.

This versatile electrochemical device is ready for commercialization as it was validated in laboratory (TRL 4) with proof-of-concept carried out regarding the determination and comparison of mass transfer and the ability for organic electrosynthesis. This technology can be applied across various industries since various electrochemical processes can benefit from the mass transfer improvement.

These electrochemical processes comprise, for example: Hydrogen Production: This technology can play a pivotal role in advancing the production of clean hydrogen via water electrolysis; Fuels Production: This technology can boost the production of fuels, such as methanol and ethanol, from the electroreduction of carbon dioxide and carbon monoxide (gaseous waste streams), simultaneously contributing to circular economy by converting waste emissions into different value-added materials; Fertilizers Production: This technology can enhance the production of fertilizers, such as nitrate-based fertilizers, from the electrooxidation of nitrogen oxides (gaseous waste streams), also contributing to circular economy and reduction of air pollution; Organic value-added products: This technology enhances the production of organic value-added products vital in food, pharmaceutical, and cosmetics industries, such as aldehydes, phenolics, and ketones, sourced either from both pure compounds or liquid waste streams; Oxidants production: This technology can enhance the production of powerful oxidants applied in the treatment and desifection of water/wastewater and surfaces/materials, which includes ozone, persulfate, and hydrogen peroxide.

Vencedores BIP PROOF 2025/2026

Projetos vencedores

Uma opção terapêutica para tratar complicações gastrointestinais, relacionadas com a diabetes, que explora a reutilização de medicamentos já conhecidos e aprovados.

Uma argamassa inovadora, sustentável e versátil, para fabrico digital (impressão 3D) que permite criar peças ou componentes com menor impacto ambiental e maior liberdade de design.

Uma terapia fisiológica, minimamente invasiva e individualizada, que tem como objetivo revolucionar o tratamento da hérnia discal apostando na modulação imunitária por design.i3S

Um programa de intervenção psicológica digital para a melhoria da saúde mental, sexual e da qualidade de vida de sobreviventes de cancro de próstata.

Uma solução limpa, segura e eficiente para a produção de hidrogénio e eletricidade diretamente em embarcações marítimas.

Uma alternativa aos atuais métodos de desinfeção nos sistemas de água que é segura, sustentável, sem consumo de energia e sem químicos nocivos.

Um modelo inovador que reproduz de forma realista a inflamação intestinal humana, permitindo testar terapias de forma mais preditiva e personalizada.

Uma tecnologia farmacológica inovadora para combater um dos maiores desafios da oncologia moderna: o cancro da mama triplo negativo, uma forma agressiva e resistente da doença.

Um biomarcador inovador na encefalopatia associada à sépsis nenatal, com utilidade clínica e capacidade de apoiar um diagnóstico mais precoce.

Um sistema inovador que, recorrendo a uma cinta confortável com sensores, permite monitorizar movimentos fetais em casa, durante o período da gravidez.