A small compact thermal chamber for material testing that allows tests in multiple positions under controlled temperature conditions.

Material analysis is necessary to characterize and evaluate the quality and performance of materials. In addition to the traditional tests of tension/compression and axial bending/rotation in testing machines, it is often necessary to know the behavior of materials at different temperature conditions. Thus, temperature chambers are used around the tested specimen. Commercially available thermal chambers for material testing are available but operate only in fixed supports. Moreover, their configuration doesn’t prevent the excessive heat transfer to the specimen. The commercially available thermal chambers are also of relatively large size and usually weigh hundreds of kilos which blocks their portability. The present technology overcomes these three issues, with a small dimension, a reconfigurable configuration and with air flow channels that allow the cooling of the specimen.

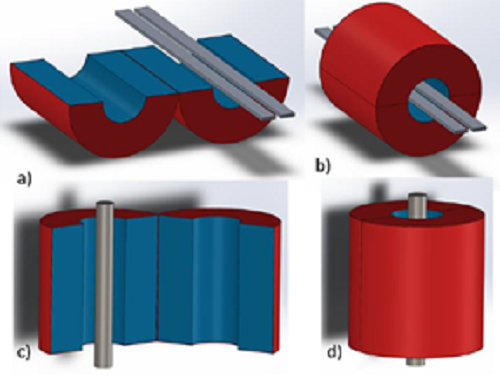

The technology allows the realization of mechanical tests under thermal loads with precisely controlled heating and cooling ramps. The chamber can be used with the axis of specimen oriented horizontally, vertically or in any other orientation. This thermal chamber ensures the homogenous temperature inside the chamber reducing the internal and external dimensions of the thermal chamber. This is achieved through an aperture insulation mechanism based on an air barrier. This mechanism also avoids excessive temperature gradients on the samples under testing. The insulation enables the cooling/heating of the temperature of the outer wall of the chamber too, so that the outside temperature of the chamber does not reach too high or too low values, which is extremely useful to ensure user protection. The specimens may be exposed to constant temperatures or gradient temperatures. Gradients may be useful to mimic some occurrences to which materials are subjected in day-to-day life. The possibility of adaptability of the thermal chamber to different configurations of a testing machine is also a great advantage allowing more scenarios to be simulated and a wider range of testing machines can be used.

This invention constitutes a complete thermal chamber system with potential to be successfully introduced in the thermal chambers market. This thermal chamber is compatible with all commercial material testing machines. The main customers of material testing machines are research organizations and industries with strong R&D on material properties, for instance, automotive, mobility, energy and aerospace sectors. The thermal chamber was designed and simulated. Its materialization in a prototype is currently a work in progress.